Screen Printing Jobs: Opportunities and Career Insights in 2025

- Screen 27

- Oct 7, 2025

- 4 min read

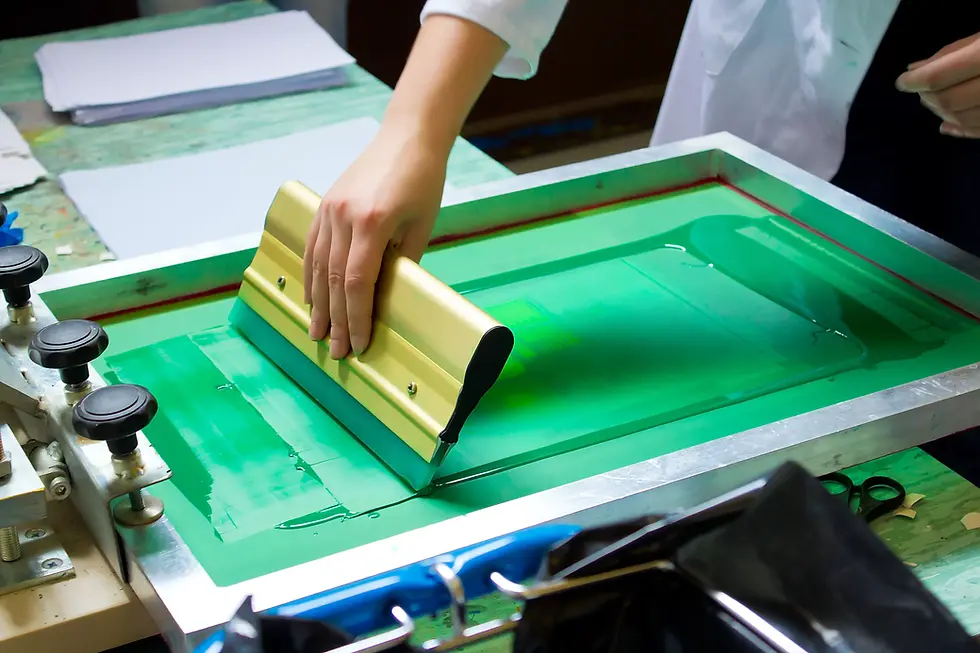

Screen printing jobs involve creating printed designs on materials like fabric, paper, or plastic using specialised screens and ink. These roles range from entry-level operator positions to skilled technician and production management jobs.

The core of a screen printing job is precision and efficiency to produce high-quality prints consistently. London screen printers play a vital role in maintaining these standards across the industry.

Many screen printing roles offer opportunities to develop technical skills. Advancement into supervisory or design-related positions is common for motivated individuals.

The industry serves various sectors, including fashion, promotional products, and industrial applications. This provides diverse career paths for those interested in screen printing.

Understanding the demands and skills required can help individuals determine if a screen printing career suits their interests. London screen printers often find that experience in this field can lead to steady work and growth in a creative yet technical environment.

Key Takeaways

Screen printing jobs focus on producing detailed, high-quality prints.

Positions vary from operators to management with skill development options.

The industry offers diverse career opportunities in multiple sectors.

Understanding Screen Printing Jobs

Screen printing jobs cover a range of roles involving the creation, preparation, and operation of printing equipment. These positions require specific skills, from manual dexterity to technical understanding.

Distinct responsibilities depend on the job type. London screen printers need to adapt to various roles within the process.

Types of Screen Printing Positions

Screen printing roles vary from entry-level to specialised positions. Common jobs include screen printers, who operate the machinery to apply ink to materials like textiles, glass, or plastic.

Pre-press technicians prepare screens by creating stencils using light-sensitive emulsions. Other positions include press operators, responsible for machine maintenance and setup.

Quality control inspectors ensure prints meet client specifications. In larger companies, roles like designers or production managers may overlap with screen printing to coordinate workflows or develop print designs.

Each role focuses on stages of the screen printing process. London screen printers require a blend of technical knowledge and attention to detail.

Key Responsibilities in Screen Printing

Screen printers typically:

Prepare screens by coating them with emulsion

Set up and align materials on printing presses

They also mix inks to match colour specifications. Operating manual or automated screen printing machines is a core part of the job.

Monitoring print quality throughout the production run is essential. Pre-press technicians must accurately create stencils through a process called exposure.

Maintenance tasks, like cleaning screens and adjusting equipment, are ongoing responsibilities. This helps prevent defects and ensures smooth production.

Quality control involves inspecting prints for colour accuracy, alignment, and consistency. London screen printers also document production details and maintain safety compliance.

Required Skills and Qualifications

Successful screen printing workers must have a keen eye for detail and good hand–eye coordination. Practical experience with screen printing machinery and techniques is highly valued.

Technical skills include understanding colour mixing, screen preparation, and machine operation. Familiarity with safety standards and basic maintenance is important.

Some roles require knowledge of design software or print production processes. Qualifications vary: many screen printers start with no formal education but gain skills through apprenticeships or on-the-job training.

Advanced positions might require a diploma in print technology or related fields. Communication skills and the ability to follow instructions precisely are essential across all roles.

London screen printers benefit from continual learning and skill development.

Career Paths and Progression in Screen Printing

Screen printing offers clear routes for growth, from hands-on roles to technical or managerial positions. It also provides chances to specialise in different printing techniques or move into related areas such as design or production management.

Entry-Level Opportunities

Entry-level roles typically include positions like press operator assistant or production technician. Individuals in these roles focus on basic machine operation, material preparation, and maintaining workspace cleanliness.

These jobs require attention to detail and mechanical aptitude but usually do not demand prior experience. London screen printers often receive training on the job to develop skills in screen setup, ink mixing, and quality control.

Basic knowledge of health and safety regulations is essential at this stage. Entry-level roles serve as a foundation for understanding screen printing workflow and equipment.

Advancement and Specialisation

With experience, screen printers can advance to lead operator or supervisor roles. These positions involve managing print runs, training junior staff, and troubleshooting technical issues.

Specialisation options include working with advanced techniques such as plastisol inks, discharge printing, or textile printing. Alternatively, some choose to focus on the design and pre-press side, mastering artwork preparation and colour separation.

Certification courses and apprenticeships can bolster progression. London screen printers with the ability to manage larger projects or workflow processes often move into roles in production planning or quality assurance.

Work Environments in the Industry

Screen printing jobs exist in diverse environments, from small boutiques to large industrial plants. London screen printers can be found in both settings, adapting to various client needs.

Smaller shops often require workers to perform multiple tasks, including printing, cleaning, and packing. London screen printers working in these environments may find themselves involved in every step of the process.

Larger companies usually have specialised teams, separating design, printing, and finishing departments. The pace and physical demands can vary widely.

Some positions require standing for long periods and manual handling of materials. London screen printers in big facilities often focus on specific tasks within a fast-paced workflow.

Workplace culture may also differ, with some employers emphasising innovation and custom jobs. Others focus on high-volume, standardised output, which can influence the experience of london screen printers across the industry.

For a deeper understanding of local industry practices, check out our Screen Printing UK blog, or explore how traditional methods compare in Screen Printing vs DTG.

Comments